BUTTON-HOLE MACHINES

which include

Buttonhole Sewing Machines,

Buttonhole Attachments for ordinary Sewing Machine

and

Button Sewing Machines

Buttonholes are reinforced holes in fabric that buttons pass through, allowing one piece of fabric to be secured to another. The raw edges of a buttonhole are usually finished with stitching. This may be done either by hand or by a sewing machine.

Types of buttonholes

Hand stitching

1. A plain buttonhole is one in which the raw (cut) edges of the textile are finished with thread in very closely spaced stitches, typically the buttonhole stitch. When stitched by hand, a slit is made in the fabric first and the result is called a hand-worked buttonhole or worked buttonhole. The buttonhole construction sometimes includes a technique called stranding where a flat piece of gimp cord or thread is incorporated into the edges to act as a reinforcement.

2. A Milanese buttonhole: after the hole for the button is cut, a length of silk thread called a gimp is laid around the edges. A glossier buttonhole thread is then wrapped around the gimp and sewn through the cloth surrounding the buttonhole. It is used in bespoke menswear as a detail to embellish the jacket because it serves no purpose other than to hold lapel pins and flowers.

Machined stitching

Sewing machines offer various levels of automation to creating plain buttonholes. When made by machine, the slit between the sides of the buttonhole is opened after the stitching is completed.

1. A machine-made buttonhole is usually sewn with two parallel rows of machine sewing in a narrow zig-zag stitch, with the ends finished in a bar tack created using a broader zig-zag stitch. One of the first automatic buttonhole machines was invented by Henry Alonzo House in 1862.

2. A bound buttonhole is one which has its raw edges encased by pieces of fabric or trim instead of stitches

3. A keyhole buttonhole is a special case of a thread-finished buttonhole that has a round hole at the end of the buttonhole slit, reinforced with a fan-shaped array of stitches. Because a button-closed gap in a garment is normally under some stress, the button will tend to move towards the end of the buttonhole closest to the gap in the garment. A keyhole at the end of the buttonhole closest to the gap accommodates the button's shank without distorting the fabric. Keyhole buttonholes are most often found on tailored coats and jackets. This buttonhole is normally machine-made due to the difficulty of achieving it by hand working.

Buttonholer

A buttonholer is an attachment for a sewing machine which automates the side-to-side and forwards-and-backwards motions involved in sewing a buttonhole.

Most modern sewing machines have this function built in, but many older machines do not and straight stitch machines cannot sew a zigzag stitch with which buttonholes are constructed. A buttonholer attachment can create buttonholes from any sewing machine capable of making a lock stitch. (That is not to say, however, that some industrial buttonhole machines cannot employ a chain stitch, especially to create the purl when making keyhole buttonholes).

The buttonholer's adaptor attaches to the machine's presser bar, replacing the presser foot. In its place the buttonholer employs a cloth clamp with teeth on the underside to hold the material firmly whilst manipulating the cloth side to side and forwards and backwards. Driven by the up and down stitching motion of the needle bar via the fork arm straddling the needle clamp, it executes the series of movements to complete a buttonhole by moving the material rather than by moving the needle position. Buttonholers usually include a metal feed cover plate to cover the machine's feed dogs, so that they do not interfere with that of the buttonholer, though some machines allow the feed dogs to be disengaged or "dropped".

From Wikipedia, the free encyclopedia

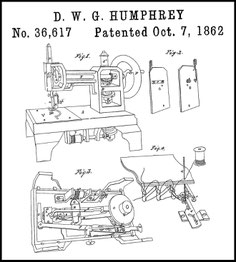

One of the earliest Button-Hole Machine

No button hole stitching machine of this class was in use prior to that invented by Daniel W. G. Humphrey, patent US 36.617 dated Oct. 7, 1862.

extract from patent US 207.173 dated August 20, 1878

...All sewing machines are furnished with special appliances for hemming, binding, braiding, tucking, &c.; indeed, there are only two operations they cannot perform satisfactorily, viz:

sewing on buttons and stitching button-holes

... A thoroughly practical button-hole machine is much wanted and would be a fortune to the lucky proprietor...

Journal of the Society of Arts (London 1863)

... 18 patents issued between 1846 and 1880 by inventors (Bachelder, Singer, Wilson, Grover & Baker, Gibbs) to produce a Buttonhole Machine. All of these quite impractical for use in production. ...

*********************************************************

LIST OF BUTTONHOLE MACHINES COMPANY

and their inventors

********************************************************

The first patent for an attachment was issued in 1853 to Harry Sweet for a binder, used to stitch a special binding edge to the fabric. Other related attachments followed; among these were the hemmer which was similar to the binder, but turned the edge of the same piece of fabric to itself as the stitching was performed. Guides for stitching braid in any pattern, as directed by the movement of the goods below, were also developed; this was followed by the embroiderer, an elaborate form of braider.

The first machine to stitch buttonholes was patented in 1854 and the first buttonhole attachment in 1856, but the latter was not practical until improvements were made in the late 1860s. Special devices for refilling the bobbins were invented and patented as early as 1862 and the popularity of tucked and ruffled garments inspired inventors to provide sewing machine attachments for these purposes also.

Grace Rogers Cooper

1864

Union Button Hole and Embroidery Machine Company of Boston

(Kasimir Vogel of Chelsea, Ma. - close to Boston)

1864

American Button-Hole, Cording, Braiding and Embroidering Sewing Machine (Company ?)

(advertisement - Dessau & Pincus assignees of G. Ruhfuss of Philadelphia)

1864

American Button-Hole Sewing Machine Company

(George Rehfuss of Philadelphia)

1865

American Button Hole Sewing Machine Company

(George Rehfuss of Philadelphia)

1867

American Sewing, Overseaming and Button-Hole Machine Company

(from advertisement - of Philadelphia)

1867

American Button-Hole Machine Company

(advertisement)

1867

American Button-Hole Sewing Machine Company

1867

American Button-Hole, Cording, Braiding and Machine Company

(George Rehfuss of Philadelphia)

1867

American Button-Hole, Cording, Braiding and Embroidering Machine Co.

1868

American Button-Hole, Cording, Braiding and Embroidering Machine Co.

1868-69

The "Hannover weekly paper for trade and commerce" reports in No. 45, p.368 of the previous year, about a new recommended buttonhole sewing machine sent to the permanent trade exhibition by Mr. Timmann in Hanover, which deserves to be called the most excellent of its kind by combines the properties of a machine that can be used for ordinary lockstitch with the buttonhole sewing machine and is also the simplest construction of a usable buttonhole machine that has become known up to now.

1869

Knopflochmaschinen-Fabrik Conring & Voigt (Berlin)

Extract from Letters Patent US 218.738, dated August 19, 1879 :

... I sometimes prefer, however, in making these improved buttonholes, to use what is known as the “Julius Gutmann two-needle sewing-machine”, patented in the United States in the year 1869... Max Hermann

US 90.528 Julius Gutmann May 25, 1869

1868-1887

American Button-Hole, Overseaming & Sewing Machine Company

(George Rehfuss of Philadelphia)

1886 National Buttonhole Co., 30 W. 14th, New York

1880 Universal Buttonhole Attachment Co. 18 E. 14th, New York

1886 Universal Buttonhole Attachment Co., 6 W. 14th, New York

1880-6 Harris Buttonhole Co. (Limited) 265 Broadway, New York

1934 International Button Hole Sewing Machine Co.

*********************************************************

LIST OF INVENTORS and their assignees

*********************************************************

Vogel Kasimir

Assignor to the

Union Buttonhole and Embroidery Machine Company

October 4, 1859 and November 1, 1864

*********************************************************

Humphrey Daniel W. G.

Humphrey Eugene

Union Button-Hole Sewing Machine Company

*********************************************************

Goodes E. A.

Miller E. L.

Assignors to:

C. S. Patterson, E. Pincus, A. Hart, M. Moore, A. Mitchell and H. H. Reed

July 26, 1859 and February 9, 1864

and

American Button-Hole, Cording, Braiding and Embroidering Machine Co.

January 29, 1867

*********************************************************

*********************************************************

Peabody Rufus H.

*********************************************************

Beuttel Charles

Braüch Philip P.

*********************************************************

*********************************************************

THE REMINGTON BUTTON-HOLE MACHINE

Among the thousands of curious machines seen by the visitors to Machinery Hall, one of the most novel is the Remington button hole machine. Since the advent of the sewing machine, many attempts have been made to produce something that would make a button hole and usually such efforts have been directed toward an attachment for an ordinary sewing machine.

So far as known, such efforts (either as an attachment or a complete machine) have been attended with only partial success and until the production of the Remington machine no device for completely finishing a button hole has been a perfect success.

Scientific American 1876

Some sensible woman has said that she would be more pleased to have her daughters learn how to make buttonholes than she would to have them learn to perform on the piano. This isn’t poetry, but it sounds refreshing.To make a buttonhole properly, measure and mark the places where the slits are to be cut. About one-sixteenth of an inch from the pencil mark, back stitch, with needle and thread, all around the mark designating the size of the buttonhole. Then cut sharply along the line, from end to end and overcast from inside to outside, from slit to back stitched outline. Then the buttonhole is ready to work. It is usually best to begin the work at one side. Set the needle, without knotted thread, into the buttonhole. Hold the slit of the buttonhole toward you and work from left to right. Throw the thread back to the left and upward away from the needle. Set the needle, in to the material just back of the back stitched line and bring the point of the needle under the goods and through the slit as close as possible to (he preceding stitch. In case B were finished stitch, C should be as close as possible to B. Holding the work with the forefinger and thumb of the left hand take thread at the head of the needle between the forefinger and thumb of the right hand and draw the thread to the left, down and under the point of the needle, then draw needle carefully toward you. The loop drawn over the n…e point forms what it known as the ''bead" and this unites with other beads to make a hard, substantial edge for the buttonhole. If there is to be great strain upon the buttonhole, or if the material is not of the strongest, a short piece of tape ii sometimes set between the folds of goods at the lower end of the buttonhole. The stitches taken through the goods and the tape holds it securely and the strength of the button hole is doubled.

The Tacoma Times April 26, 1904