Continental Manufacturing Company

18 Beekman Street , New York

Est.

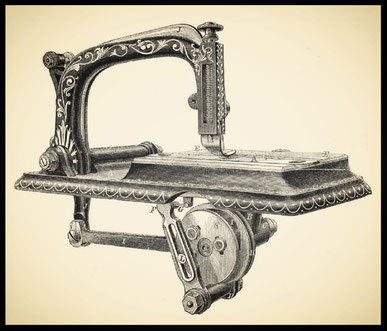

Earle Harry Smith's Cranck-Motion Shuttle Sewing Machine

Improved Sewing Machine

The inventor or author who cuts loose from conventionalities and strikes out a new path, is certain to achieve a more enduring success than those who accept what is as right in principle and proceed to engraft on that.

Until the year 1852, the mode generally adopted of operating the needle and shuttle in the sewing machine, was to stop each instrument during the operation of the other; this necessitated the use of cams to impart the motion so as to cause the stop or "rest" at precisely the right moment and up to that time no shuttle sewing machine had been made without cam motions either on the needle or shuttle, or both. In that year the inventor of the sewing machine herewith illustrated commenced his experiments. Rejecting the cam and all other like devices for operating the sewing instruments, as totally unadapted to the inevitable prospective requirements of the machine, and taking the simple elements(needle and shuttle) disencumbered of the usual devices for imparting their motions, he set out to produce a radically new system of mechanism for operating these instruments.

In the year 1854 he exhibited to the editors of this journal a shuttle machine with his new combination of movements, the needle being worked as it never had been before in such a machine, viz., by a true eccentric, imparting an easy and continuous motion; while the shuttle, driven by a crank pin, also had a continuous and uninterrupted movement ,a combination altogether unlike any sewing machine then known while the whole construction was exceeding novel an very simple. This, we believe, was the first shuttle sewing machine ever made having continuous or crank motions. Since then Mr. Smith has obtained, in all, eight patents for improvements looking to the perfection of this class of machines, in nearly all of which the continuous or crank motion prevails throughout. In the present machine he has embodied some of the most important results of his experiments for the past twelve years, making a lock stitch by a needle and shuttle having continuous or crank motions imparted by a very direct and simple mechanism. The needle and shuttle are also operated or moved relatively, so as to draw the threads into the work in a manner that adapts the machines especially to thin fabrics, while the usual adaptability to heavy work, which characterizes the shuttle machine, is retained intact. Fig. 1 is a perspective view of the machine, and reveals all the working parts except the feed bar, which is seen in the sectional view, Fig. 2.

All the working mechanism, except the needle arm, is arranged upon a single casting, consisting of the shuttle race, A, hanger, B, boss, C and pendent D. This casting is set into an opening made for the purpose in the bed plate, E and secured therein so as to form a part thereof. The boss, C, is the bearing of the main shaft and the pendent sustains the fulcrum pin of the vibrating lever, F, which gives the reciprocating motion to the shuttle driver through the connecting link, G. The driving pulley, IT, has an eccentric cast on the outside, which is encircled by one end of the strap or connection, I and the other end is attached to the lower extremity of the needle arm J. To the eccentric is attached a disk, K, with a crank pin L, moving in a groove or slot in the lever F. The disk is adjustable on the eccentric for the purpose of timing the needle and shuttle. The feeding device (see Fig. 2) consists of the bar, M, which has an up-and-down and back-and-forth movement imparted by an to eccentric N. 0 is the shuttle driver; it is attached to a slide P and receive its motion from the vibrating lever F. The slide P, runs in a dovetail groove, one side of which is solid and the other formed of an adjustable plate Q, by which it is always kept up to its bearings. All the movements of the machine being continuous and effected by the crank or eccentric, it is evident that the machine will run very quietly. No rattling nor backlash can occur, as every part is made adjustable, to follow up the wear, thus imparting the highest degree of durability. The simplicity of this machine is apparent, indeed it would be difficult to produce the three independent movements of needle, shuttle and feed, with a less number of actuative parts. These sewing machines are made by the Continental Manufacturing Co., No. 18 Beekman Street, (A. W. Goodell, Agent, Box 3.631), New York. The patent for this invention was allowed on September 7, 1865; the invention has also been patented in Great Britain and France and other foreign patents are pending.

from : Scientific American 1865